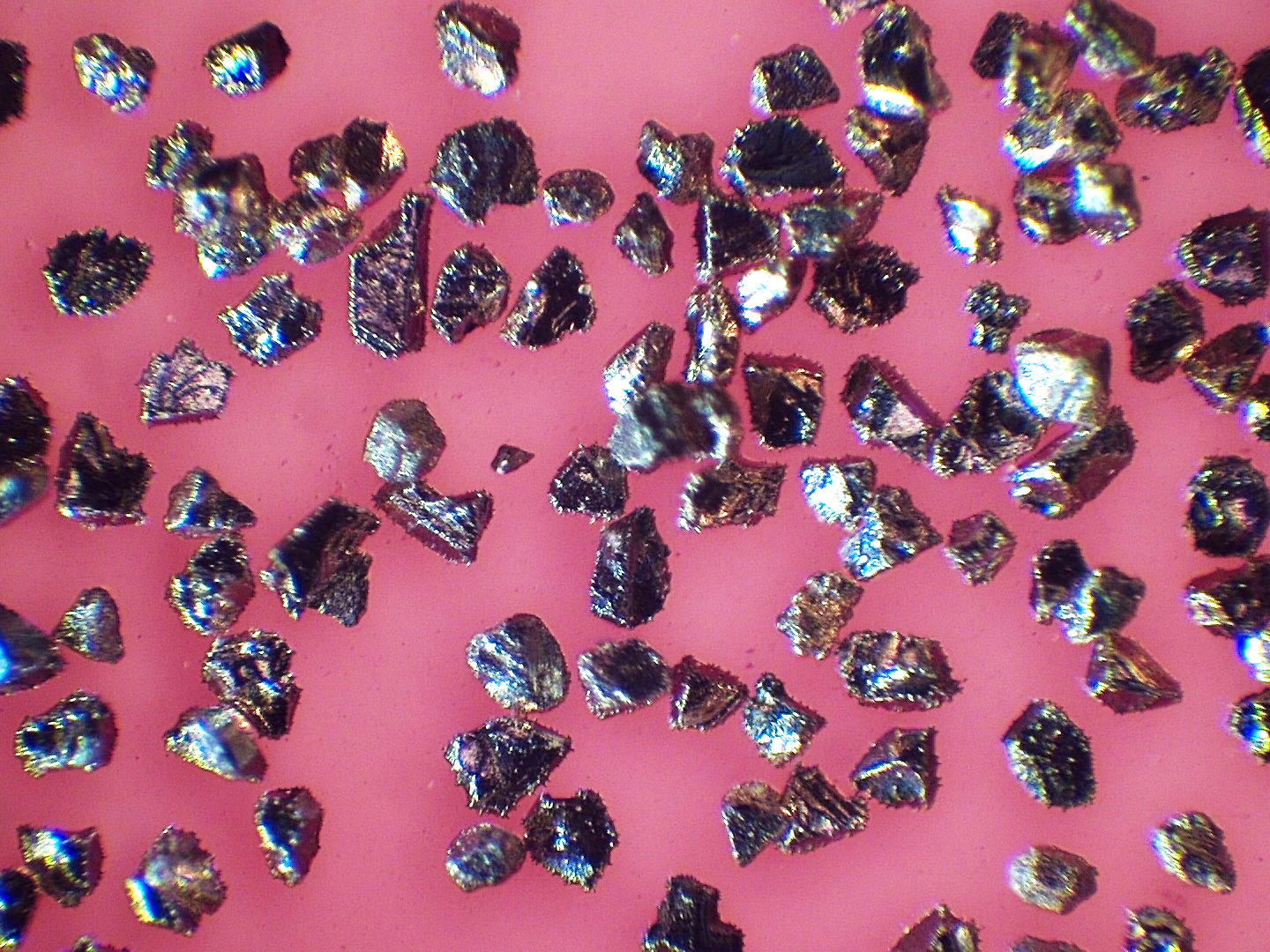

Production Introduction

Common mesh size is from #500/600 to #30/35, while other sizes are available as well.

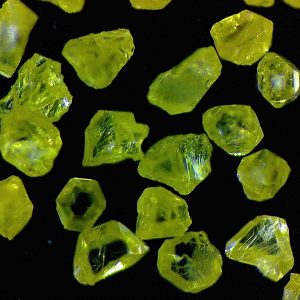

Electroplated surface with Nickel or Titanium, the material has low magnetism, accurate size distribution, high purity and high sharpness.

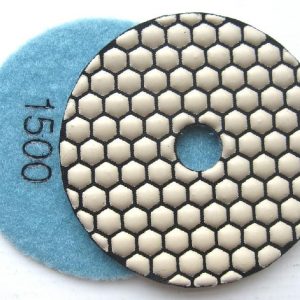

The material is most suitable for many electroplated tools including electroplated diamond wheels, grinding wheels, grinding bits, cutting tools, wire tools, etc.

Electroplated Diamond Powders Size Chart

| Product Series 55N | Product Series 33N | Size Range ( µm ) ( approx. ) |

Mesh Size |

| 55N 500# | 33N 500# | 26-32 | 500/600 |

| 55N 400# | 33N 400# | 32-38 | 400/500 |

| 55N 320# | 33N 320# | 38-45 | 325/400 |

| 55N 270# | 33N 270# | 45-53 | 270/325 |

| 55N 240# | 33N 240# | 53-63 | 230/270 |

| 55N 200# | 33N 200# | 63-75 | 200/230 |

| 55N 180# | 33N 180# | 75-90 | 170/200 |

| 55N 150# | 33N 150# | 90-106 | 140/170 |

| 55N 120# | 33N 120# | 106-125 | 120/140 |

| 55N 100# | 33N 100# | 125-150 | 100/120 |

| 55N 80# | 33N 80# | 150-180 | 80/100 |

| 55N 70# | 33N 70# | 180-212 | 70/80 |

| 55N 60# | 33N 60# | 212-250 | 60/70 |

| 55N 50# | 33N 50# | 250-300 | 50/60 |

| 55N 45# | 33N 45# | 300-355 | 45/50 |

| 55N 40# | 33N 40# | 355-425 | 40/45 |

| 55N 35# | 33N 35# | 425-500 | 35/40 |

| 55N 30# | 33N 30# | 500-600 | 30/35 |

Reviews

There are no reviews yet.